TV-10LE – 10L – Electric Sausage Filler – Commercial

Couldn't load pickup availability

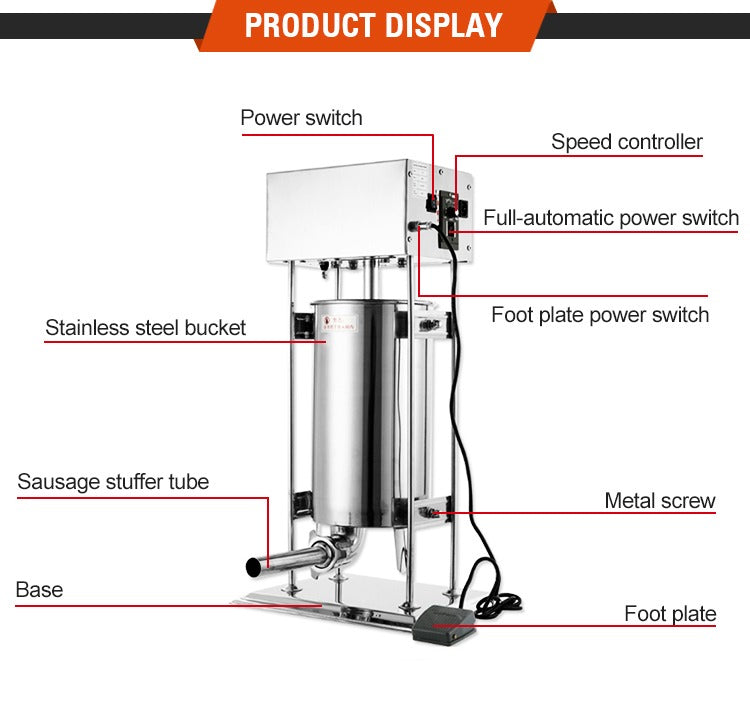

The TV-10LE is a precision-engineered electric sausage filler designed for efficient, high-volume sausage production in professional settings. With a 10-liter capacity and four interchangeable funnel sizes, this unit allows operators to produce sausages of varying diameters with speed and consistency, minimizing manual labor and maximizing productivity.

Ideal for butcher shops, commercial kitchens, delis, meat processing facilities, and catering services, the TV-10LE is built for operations that need to fill large quantities of sausages while maintaining uniformity and hygiene. Its powerful electric drive removes the need for manual cranking, reducing operator fatigue and ensuring steady output for hours of continuous use.

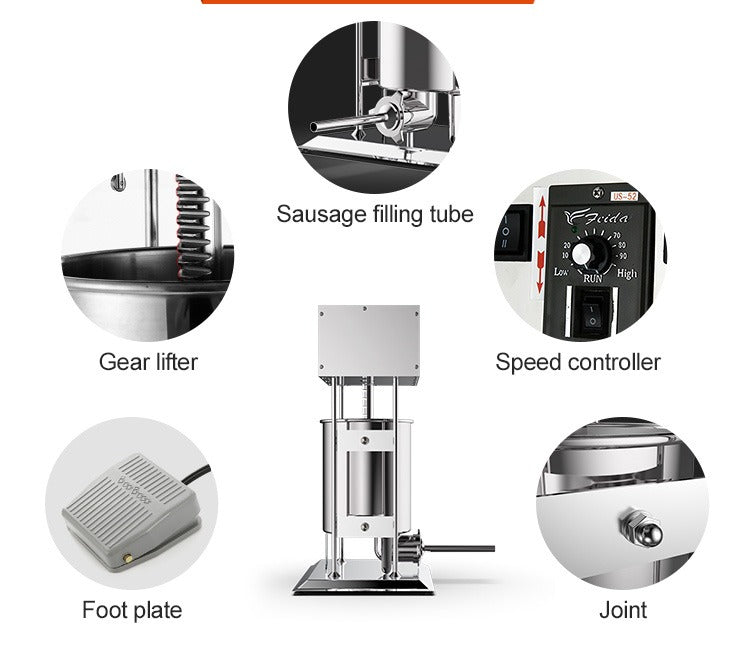

This model features a 120W motor, paired with a 220V / 50Hz power supply, delivering reliable torque for even, smooth sausage filling. The barrel measures 285*219mm, and the included nozzles (16mm, 19mm, 25mm, 38mm) give you full control over sausage size and type—from snack sticks to bratwursts and more. Its vertical design saves counter space while offering easy access for loading and cleaning.

Key Features

-

10L capacity for large-batch sausage production

-

Electric motor: 120W, 220V / 50Hz – powerful and quiet operation

-

Barrel Size: 285*219mm – optimized for high-volume use

-

4 stainless steel nozzles included: 16mm, 19mm, 25mm, 38mm

-

Hands-free operation eliminates manual labor

-

Durable, hygienic construction – easy to clean and sanitize

-

Vertical design conserves workspace and improves accessibility

Specifications

-

Model: TV-10LE

-

Type: Electric Sausage Filler

-

Capacity: 10L

-

Barrel Size: 285*219mm

-

Voltage/Frequency: 220V / 50Hz

-

Power: 120W

-

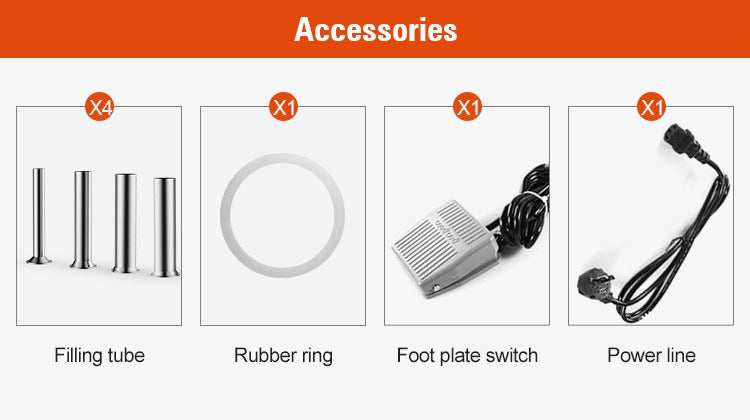

Funnel Sizes: 16mm, 19mm, 25mm, 38mm

-

Accessories Included: 4 nozzles (stainless steel)

Where to Use

Perfect for meat shops, sausage manufacturers, restaurant prep kitchens, charcuterie businesses, and farm-to-table operations that require precise, repeatable sausage filling with minimal downtime.

Maintenance & Operational Tips

-

Rinse and sanitize all contact parts after each use to maintain hygiene

-

Use food-grade lubricant on moving parts for smoother operation

-

Store nozzle attachments in a clean, dry space

-

Keep the power unit protected from water during cleaning

-

Regularly inspect the drive gear and piston for wear